Houston’s Top Mold Design Service Providers

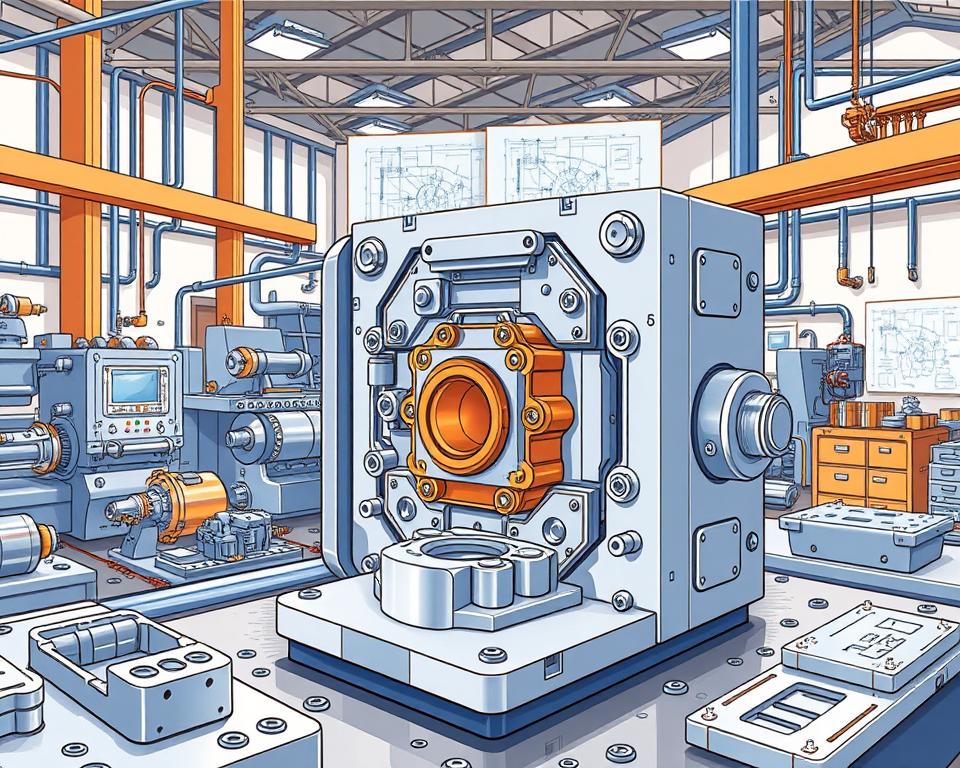

The global injection molded plastics market is set to hit $440 billion by 2025. This growth underlines the importance of professional mold design services. They develop precision mold designs tailored to varied industries. Houston’s Lowrance Machine stands out as a premier mold design firm. They offer innovative solutions for automotive, aerospace, and consumer products.

Lowrance Machine uses advanced technologies like CAD software and 3D printing. Their team ensures precision and efficiency in the molding process. With their extensive experience and technical skills, they are a reliable partner for businesses. Learn how their mold design Houston capabilities improve your initiatives and align with modern market requirements.

The Critical Role of Mold Design Services

Mold design services are vital in the manufacturing world, affecting product quality and operational efficiency. Effective mold design underpins both product function and lifespan. Investing in skilled mold design can slash costs and improve quality benchmarks.

Lowrance Machine demonstrates why veteran experts matter. They engage closely with clients to develop tailored designs. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Opting for premier mold design services elevates product functionality and powers business growth. With optimized mold design, manufacturing runs smoothly and firms gain market advantage.

Mold Design Houston: Types of Services Offered

Houston’s Lowrance Machine provides diverse mold design services customized for each sector. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Bespoke Mold Designs: Tailored mold designs crafted to precise specs.

- Prototyping: Early-stage mold prototyping to validate designs.

- Injection Molds Houston: High-quality injection molds designed for durability and precision, ideal for various manufacturing applications.

- 3D Modeling: 3D-model-driven design for superior precision.

- Mold Repair & Upkeep: Repair and upkeep solutions to maximize mold longevity.

All offerings focus on efficient production, improved product standards, and cost savings. With clarity on service options, businesses can align mold solutions with their production goals.

Why Hire Professional Mold Designers

Engaging professional mold design teams offers significant process improvements. Expect greater precision, longer tool life, and faster cycles. Tailored molds ensure top-notch quality and repeatable outcomes.

Experienced mold design experts offer insights that streamline production. They align molds with regulatory and bespoke requirements. Joint efforts spark innovation and extend product longevity.

Saving on production is a major advantage. Modern techniques curb scrap and shorten lead times. Such efficiencies translate into meaningful cost reductions. Fast-turnaround designs accelerate product launches.

Overall, professional mold services underpin manufacturing success. They dedicate themselves to streamlining operations and enriching output.

Next-Gen Mold Design Innovations

The field of mold design has seen a major leap forward thanks to technological advancements. Pioneering these advances, Lowrance Machine adopts the latest techniques. Such breakthroughs accelerate production and raise standards. Advanced mold design technologies play a significant role, streamlining the creation of unique molds and cutting down on time and costs.

Additive manufacturing shines by producing fast prototypes and intricate shapes. It slashes raw-material loss relative to traditional processes. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

Houston’s mold professionals adopt these forward-thinking approaches. Companies are gaining a competitive advantage by leveraging digital design tools and advanced fabrication methods. They support dynamic, client-focused design cycles that address varied sector requirements.

| Technique | Description | Benefits |

|---|---|---|

| Additive Manufacturing | Harnesses 3D-printer tech for swift mold fabrication. | Accelerates turnaround and minimizes waste. |

| Virtual Testing Tools | Enables digital prototype testing and refinement. | Enhances accuracy and optimizes performance. |

| Digital Design Tools | Integrates advanced software for precise mold specifications. | Facilitates customization and adaptation. |

In Closing

Professional mold design underpins both efficient operations and quality products in Houston. Professional mold design services offer expertise to tackle mold development challenges. They ensure that each company’s unique needs are met, leading to better outcomes.

Renowned for precision and teamwork, Lowrance Machine leads the mold design field. Bespoke molds and innovative methods from professionals maintain market leadership. Working with mold design experts improves product quality and streamlines operations.

Investing in professional mold design in Houston focuses on quality and efficiency. Businesses can meet customer expectations effectively and gain a significant competitive advantage. Embracing these expert offerings is key to thriving in a challenging marketplace.